Tool changing systems

Until a few years ago, the change from one pressing tool to the next was always time taking. Due to many manual operations, a tool change costs a lot of time. With MAWI’s innovative and flexible tool changing systems, these times are a thing of the past. A largely automated tool exchange in minutes ensures efficiency and productivity. MAWI will bring your production up to the technically feasible standard with modern tool changing systems.

Arrange a consultation appointment

We will be happy to advise you in detail and without obligation. Make an appointment right now.

Request an offer

We will be happy to provide you with an individual offer for our high-performance pressing and punching solutions.

Request brochure

Would you like more information? Request our brochure now without obligation.

Your advantages with MAWI tool changing systems

With our solutions for all aspects of tool change, production interruptions can be significantly minimized. Innovative and reliable tool clamping systems ensure an easy release in case of a change, and a tight fit during the normal operation of your punching or pressing tool. The MAWI tool changing systems reduce the set-up times to a minimum. Running-in and setting times for a new series can be significantly reduced.

We offer:

- Hydraulic clamping systems

- Electromechanical clamping elements

- Mechanical clamping elements

- Magnetic clamping systems

With this selection you will have a suitable clamping system for your press available for every application.

- Hydraulic clamping elements convince through very high contact forces.

- Electromechanical clamping elements are very comfortable tool clamping systems that also offer a maximum degree of warping safety.

- Mechanical clamping elements are mainly still used in forging presses where very high forces act on the tools.

- Magnetic clamping elements allow an extremely fast tool change.

They are ideally suited for applications with a fast product sequence.

Our tool changing systems are designed for a maximum machine and tool safety. Easy handling and integrated protective systems ensure a high level of safety during the tool replacement. We can equip your forming and stamping presses with the appropriate tool changing system. Give us a call, we will find the right system for your application, and enable you to make your production more efficient. We are there for you, from the first call to the integration of a new tool change system with a subsequent test run. On request, we can also take over the maintenance of your systems. With a service contract from MAWI you will ensure the productivity and reliability of your systems. We also carry out Accident Prevention Regulations (UVV) tests.

Optimized controller for tool change systems

The changing systems can also be integrated into the press controller system. Holding force and change times can be continuously monitored or recorded. We can integrate the sensors and actuators on your tool changing system into the presses. With this complete solution, you always have the efficiency and productivity of your machines under control. Our controller standard for presses, the Siemens S7, supports this integration. However, upon request we can also expand other controller systems accordingly.

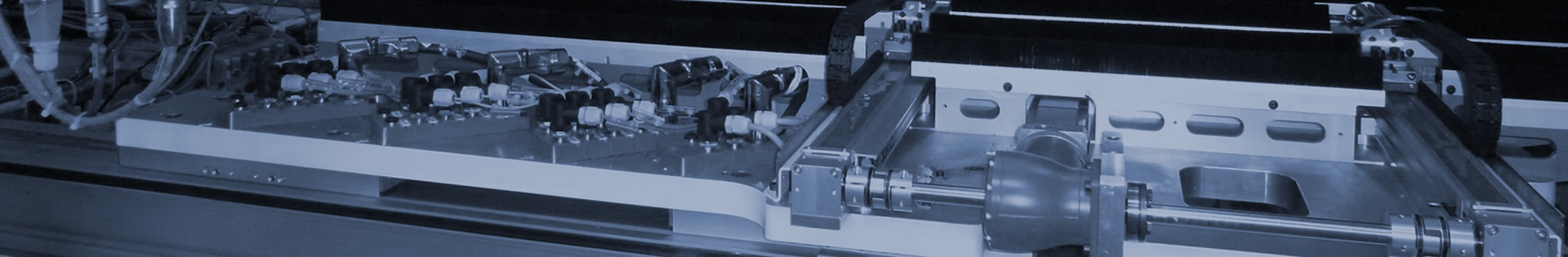

Tool changing systems in detail

For the comfortable, safe and fast change of your pressing and punching tools we offer:

- Tool changer arms for parking the tool during mounting and dismounting

- Tool clamps: Usually hydraulic, but on request also mechanical, electromechanical or magnetic

- Lift bars for supporting the lifting process and moving the tool on the press table

- Hydraulic power pack: For operating the hydraulically driven components