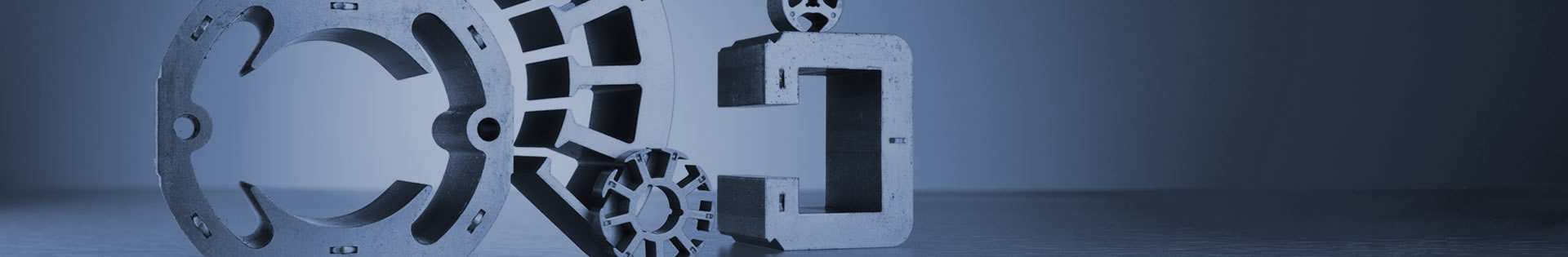

Hot forging

Hot forging is the standard process for the production of complex, solid parts with a high inherent strength. The toughness and tensile strength of hot forged components is the essential difference to die-cast parts: When casting, any geometry can be created very easily and quickly. However, the result is always so coarse crystalline that the component is unable to absorb shear and tensile forces. Hot forged components do not have this problem, they are heated to just below their melting point for forming. Through this high temperature, the parts can be shaped with low forces. Hot solid forging is a process in which speed and precision must act in a complementing manner. The component is heated as a blank in an furnace. As soon as it is removed, it begins to cool down and must be processed as quickly as possible. The subsequent hardening by quenching of the still warm part additionally preserves the newly created shape and increases the strength.

Theoretically, almost any metal can be processed by hot forging. However, it really only makes sense for very hard and brittle materials with a high melting point. A standard material that is shaped with forging presses is boron-manganese steel 22MnB5. This high-strength special material was developed for particularly demanding applications. Hot solid forging is the adequate manufacturing process for manufacturing top-quality products with these or similar materials.

Arrange a consultation appointment

We will be happy to advise you in detail and without obligation. Make an appointment right now.

Request an offer

We will be happy to provide you with an individual offer for our high-performance pressing and punching solutions.

Request brochure

Would you like more information? Request our brochure now without obligation.

Hot forging – the advantages

Setting up and maintaining a hot solid forging plant is one of the most demanding tasks in the entire field of production technology. The precise coordination between heating up the preliminary products, placing them in the hot forge, carrying out the pressing process and quenching them in the cooled die must be precisely timed. Even the smallest deviations from the specified manufacturing process quickly result in a loss of quality. This is particularly fatal with hot forged parts, because these quality losses are not recognized at first sight: In contrast to the remeasurement of tolerances, the material quality can only be determined by destructive testing. We at MAWI, with our many years of experience, can supply you with exactly the hot forging presses you need to manufacture your products. The accompaniment of your forging press from the planning to the purchase is only a part of our offer.

Hot forging is associated with a very high maintenance and care requirement like no other manufacturing process. Let us take on this complex task. We will control and inspect your press continuously at fixed intervals. We will gladly be a partner to further your success. With a safe, properly installed and fully equipped MAWI hot forging system, you can fulfil your production orders and secure an excellent market position. It goes without saying that we will also keep your systems safe: With a Accident Prevention Regulations (UVV) inspection carried out by us, you can look forward to any inspection by the employer’s liability insurance association.

Control and monitoring for your hot forging systems

A hot forming plant has a particularly high monitoring requirement. Thanks to our SIEMEMS S7 compatible controller and safety PLC, you can also keep a mobile eye on these complex processes.

Our controller offers:

- Drive with frequency control

- Monitoring of pressing force, temperature curves, flow rates

- Counters

- Safety devices of the tool

- Remote access

- Remote data transmission

- Interfaces for peripheral devices

Our services for your hot forging

Hot forging plants are highly complex systems. Give us a call and we will be happy to advise you on all your challenges for hot extrusion presses, forging plants and peripheral equipment.