Press automation

Press automation does not start foremost with the machining of the workpieces. Introducing sheet metal plates into the machining process using a blank loader, for example, is a first step in the automated production. With this measure you will not only achieve maximum efficiency, you also save your employees an increased risk of injury: Plates are sheet metal blanks which are fed into the press after separation. With a plate loader, manual a handling of these sharp-edged semi-finished products is avoided and the press is loaded with a constant positioning accuracy. Press automation is therefore also an important step towards improving process reliability.

The positioning can be carried out precisely using modern tracking systems. With the help of camera systems and marking crosses, the plates can be positioned exactly. If necessary, the precision of the press automation can be further increased by using pin holes.

Arrange a consultation appointment

We will be happy to advise you in detail and without obligation. Make an appointment right now.

Request an offer

We will be happy to provide you with an individual offer for our high-performance pressing and punching solutions.

Request brochure

Would you like more information? Request our brochure now without obligation.

Press automation – the advantages

We can adjust your plates conveying exactly according to your wishes. We will equip your machines with everything you need for the separation and precise transfer of your blanks.

We offer:

- Pre-punching of pin holes for a maximum precision positioning

- Force or form-fit pick and place grippers

- Integration into the plant controller system

- Modularized layout with a high degree of individualization

- Material-independent transfer through magnetic or vacuum systems

- Tracking systems with an optical support

- Solutions for any part weight or plate size

We will configure your press automation solutions exactly as required for a highly efficient operation of your production plant. We will accompany your plant from your initial contact establishment to us, all the way up to the successful test run in your production. Our service will also continue after the installation of your press automation: With a maintenance contract, you can be sure that these sensitive systems are always ready for operation. We can inspect your press automation at fixed intervals. By readjusting and replacing wear parts, we can thereby minimize downtimes of your systems and avoid expensive repairs.

We will also be happy to consult you if you are interested in used press automation machinery. Utilize our competence and experience for your success. Call us, we will find a solution for your challenge. Our support will ensure that your systems always comply with Accident Prevention Regulations (UVV). This ensures that you always have maximum occupational safety in your production and can document this without any problems.

Powerful controller for your press automation

We can integrate your press automation into the controller of your press. With our SIEMENS S7 compatible hardware and software, you also have the option to utilize the current industry standard for your peripheral devices. This system enables a modular structure and thus the step-by-step expansion of your entire production line. The central controller has the advantage that the individual modules can be precisely synchronized. This avoids a permanent readjustment or respectively a “build-up” is prevented, as can often occur with customized solutions.

Special solutions are also implemented by us. Call us, we love every new challenge.

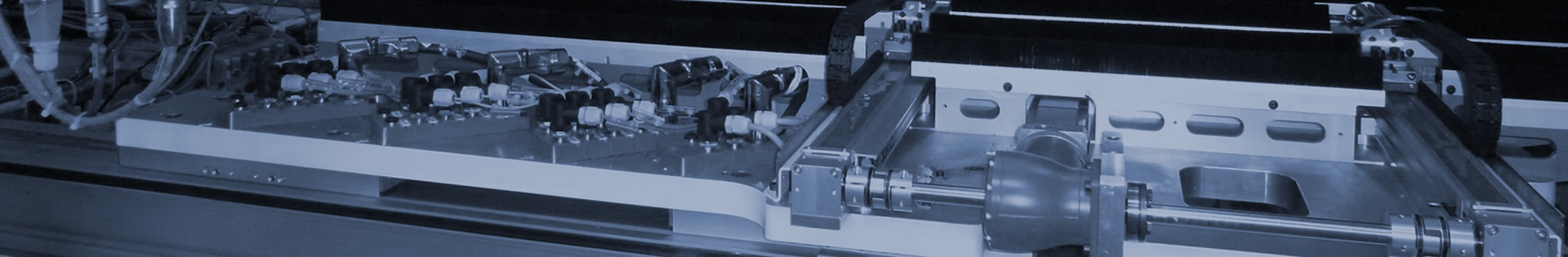

Press automation – our product range

For the automation of your presses we can supply:

- Mechanical transfer systems

- Cam-controlled transfer systems

- Transfer systems directly driven by the press

- 2 and 3-axis gripper bar transfers with a maximum degree of flexibility, dynamics and reliability

- Force-fitting lifting systems using vacuum or magnetic plates

- Form-fitting lifting systems with pick-and-place grippers

- Special applications, such as electronically controlled inserters