High-speed stamping machines

With the high-speed stamping machine, large quantities can be produced in the shortest possible time. This is achieved by extremely high stroke rates: 1400 strokes/minute and more are not uncommon in modern high-speed stamping machines.

These high speeds naturally generate strong vibrations that must be absorbed. In addition, high punching forces sometimes occur during this manufacturing process: 300 – 4500 kN are the usual values for high-speed stamping. The stamping press must therefore have a robust frame construction so that the forces can be absorbed and the slide guide has the necessary precision so that the tool is not overstressed. For our high-speed automatic stamping machine, we rely on two-part base frames made of cast-iron. With the aid of a static and dynamic mass compensation, the resulting vibrations are compensated or damped to such an extent that no damage to the machine or tool can occur.

With high-speed stamping machines, it is possible to manufacture inexpensive components for complex applications.

Products commonly manufactured with this process are:

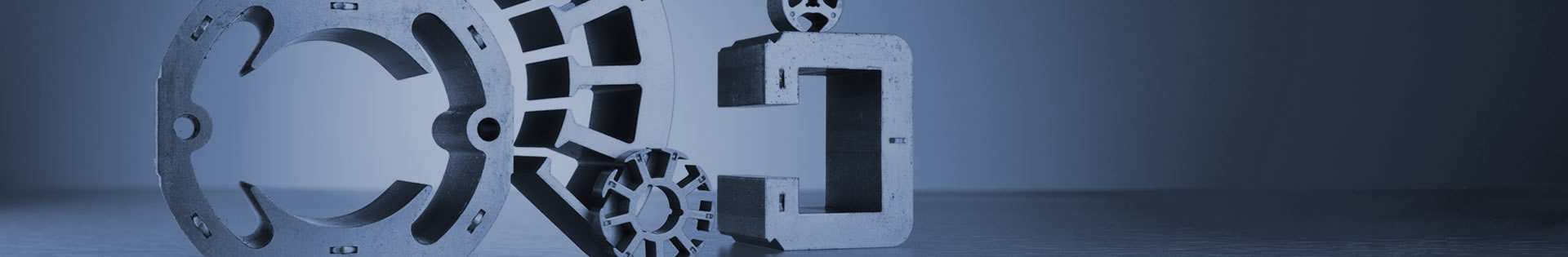

- Rotor and stator laminations for generators and electric motors

- Metal sheets for transformers

- Small parts for the hardware industry

- Stamping parts for the automotive industry

- Components for household appliances

- and much more

Arrange a consultation appointment

We will be happy to advise you in detail and without obligation. Make an appointment right now.

Request an offer

We will be happy to provide you with an individual offer for our high-performance pressing and punching solutions.

Request brochure

Would you like more information? Request our brochure now without obligation.

Advantages of MAWI high-speed stamping machines

A high-speed stamping machine is a demanding machine that requires regular maintenance. We at MAWI offer our maintenance service, in order to minimize the downtimes of your stamping press and to extend the service life. We are specialists when it comes to stamping and forming technology, and can optimize your high-speed presses, single-column presses, double-column presses or automatic punching machines for use as high-speed stamping presses, by integrating state-of-the-art peripheral equipment and controller systems for your production.

Our offer also includes a comprehensive after-sales service. We will accompany your high-speed stamping press from the project planning to the test run in your production hall – and beyond. Sign a maintenance contract with us, and we will guarantee you the best possible productivity and service life for your machine. We will also constantly maintain your machines compliant with the latest safety standards: With a maintenance and inspection by us, your systems will pass every Accident Prevention Regulations (UVV) inspection at the first attempt.

Innovative controller system for the high-speed stamping presses

We will equip your high-speed stamping press with a SIEMENS S7 compatible controller. This ensures that your equipment meets the industry standards, and is ideally equipped for the present and the future. With our controller we can expand your high-speed stamping presses by the following items:

- Drive with frequency control

- Monitoring of envelope curve and pressing force

- Electronic switching controller for cams, counters and timers

- Various counters

- Integrated article management

- Expansion option through interfaces and switchable sockets

- Remote data transmission

- And much more

Your high speed punching machine from MAWI

Our high-speed stamping presses offer:

- High-strength, two-piece cast-iron press frame

- Pressing forces up to 4500 kN

- Dynamic mass balance

- Damped slide guidance

- Motor-hydraulic slide adjustment

- Rolling bearings or hydrodynamic bearings for eccentric shafts

- HERION safety valves for presses

- Optional high-speed feeds, mechanical or with servo drive

- Optional peripherals, that are best suited for your machine