Press transfer

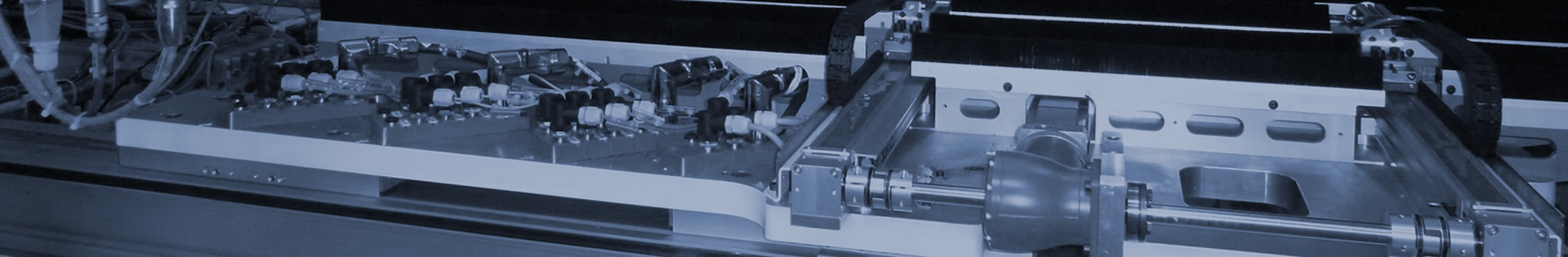

Press transfer systems are the answer to the demand for a safe, continuous and efficient production. Instead of transporting the workpieces from one processing station to the next by hand, our part feeding modules do this automatically. Through a gripper rail transfer and similar technical solutions, we can achieve a precise transfer of your components in exactly the cycle time required by your press. Even demanding components are no problem for our automatic part feeding system. Our press transfer solutions can handle light and small workpieces just as reliably as heavy, hot or sharp-edged semi-finished and end products.

We can offer you:

- Complete transfer systems for hot extrusion presses, semi-hot extrusion presses or cold extrusion presses

- Highly dynamic 2-axis transfer feeds

- Highly dynamic 3-axis transfer feeds

- Gripping tools and exchange rails

For your press transfer, we fully rely on highly rigid linear units. The movements are performed by servo motors with integrated planetary gears. The modules can be expanded by any number of grippers. This transfer mechanism is much stiffer than an joint arm robot. Our press transfer solutions thus support your success through a precise handling, reliable implementation and a long service life.

Arrange a consultation appointment

We will be happy to advise you in detail and without obligation. Make an appointment right now.

Request an offer

We will be happy to provide you with an individual offer for our high-performance pressing and punching solutions.

Request brochure

Would you like more information? Request our brochure now without obligation.

Advantages of a MAWI press transfer

The servo transfer controller is not self-sufficient, but a component of the central press controller. The integrated press controller thus acts directly on the individual servo motor on the transfer system. This approach enables a high-precision control of the transfer modules. Ultimately, the transfer speed is only limited by the physical limits of the processing machine. This enables you to use your pressing or stamping machine with a maximum efficiency.

In addition to the delivery of complete systems, we can also equip your existing systems with a reliable and high-performance press transfer system. Virtually any forming or stamping press can be improved in efficiency, safety and productivity with an automatic part feeding.

We are happy to accompany you from the first call, all the way up to the successful test run of your automated pressing or stamping line in your production. We will be there for you, even after the successful installation: A maintenance contract with MAWI ensures the maximum degree of reliability and productivity for your automated manufacturing systems. We will inspect your systems at regular intervals, and thus avoid expensive repairs through adjustments and timely replacement of spare parts.

Our press transfer is designed according to the state of the art, taking into account all applicable standards and regulations, with particular emphasis on safety issues.

We know exactly what is important when it comes to avoiding dangerous situations in automated production environments. Ensuring Accident Prevention Regulations (UVV) and CE conformity gives you the reassuring feeling of always operating safe systems. You can look forward to a visit from the employers liability insurance association with confidence.

Efficient controller for the press transfer

We will equip your pressing and punching lines with the proven SIEMENS S7 controller system. This modern system already provides interfaces for press transfer solutions. The expansion of your production plant through a solution by means of press transfer is thus quick and easy to carry out. Special applications, or a step-by-step, modular expansion can also be easily implemented using S7 controllers. Give us a call, and we will be happy to equip your existing systems or a used machine with a SIEMENS S7 compatible controller system.

Our range of products revolving around the press transfer

We can offer the following solutions for the automation of your production lines:

- Mechanical transfer systems

- Cam-controlled transfer systems

- Directly driven 2-axis gripper rail transfer systems

- 2 or 3-axis servo gripper rail transfer systems with a maximum degree of flexibility

Each transfer system can be equipped with all available inserts. Should you require a special solution, please do not hesitate to contact us. We are able to configure your transfer system exactly according to your needs and, if necessary, completely redesign the pick-and-place systems.